THE FUTURE OF HIGH FREQUENCY EQUIPMENTS CONNECTION

DESCRIPTION OF LITZ WIRES

Utilisés dans les applications de transport de courant à hautes fréquences, les fils de Litz sont construits avec des fils de cuivre émaillés de petit diamètre (0,04 mm à 5 mm), isolés électriquement et tressés les uns des autres pour réduire les pertes « effet de peau » que générent les courants électromagnétiques opposés (courants Eddie). Aussi, en basses fréquences, on considère ce phénomène comme négligeable, bien que certains spécialistes de conversion d’énergie estiment que des pertes sont mises en évidence dès les basses fréquences.

WHY ENAMELLED COPPER WIRES?

Avec des fils de cuivre simples, qui possèdent une résistance faible, le courant électrique aura tendance à circuler à la périphérie du conducteur. L’impédance augmentera alors, et le pourcentage de pertes augmentera en fonction que l’impédance augmentera, constatant que l’augmentation de résistance va croître beaucoup plus vite que l’augmentation de la section. L’utilisation de fils multibrins permettent de diminuer les pertes grâce à la réduction de la résistance HF, par effet de peau et courant de Foucault. On comprend ainsi que l’utilisation de fils de cuivre simples dans les équipement modernes comme les transformateurs, électro-aimants ou alternateurs peut conduire à des catastrophes. Les câbles sont construits de telle sorte que les pertes « d’effet de proximité » sont également réduites. On choisira aussi le type de vernis selon la classe de température (de 150 à 240 ° C).

Note that the diameter of the unitary wire will be chosen according to the frequency at which it is desired to work, so that their diameter is smaller than the thickness of the skin. See table below.APPLICATIONS

Mainly used for power conversion, high frequency transmission and reception, power electronics, inductive proximity switches, electronic tags, multiple telephone transmission equipment, coil windings, flexible connections for relays, coils, transformers, motors, etc.

Our manufacturing site based in Spain enables international delivery of our solutions. We also offer unitary enamelled copper wires.

Construction

Conductor

Litz's thread is a enamelled copper wire which may be weldable or non-weldable in Grade 1

(1 coat of enamel) or Grade 2 (2 coats of enamel)

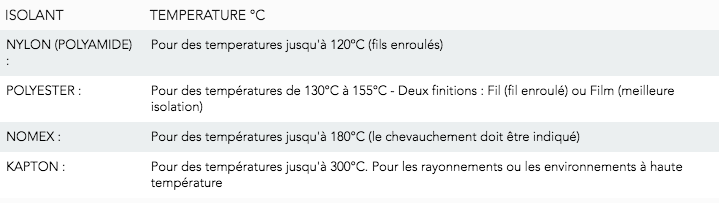

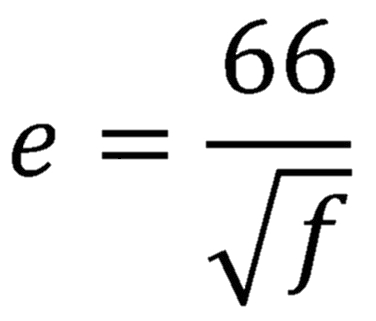

THERMAL CLASS | F155 (155°C) | H180 (180°C) | 200 (200°C) |

|---|---|---|---|

Enamel type | Polyurethane | Polyester or Polyurethane | Polyester ou polyamide |

Wiring

Conductors wired in 7-wire studs and these wired in a perfect wiring formation (7, 19, 37) with a suitable pitch. The formation and number of threads depend on the section and the working frequency thereof. We can also manufacture in square or rectangular shape, as needed.

Insulation: According to different materials, according to the temperature and their use

Characteristics

Cables made of fine enamelled copper wire. Unit threads from 0.05 mm Ø to 5 mm

The choice of the diameter of a single wire is important for the specific application

The table below shows the relationship between the recommended single wire diameter and the frequency range.

Frequency Min (KHz) | Frequency Max (KHz) | Recommended wire diameter (mm) |

|---|---|---|

0,06 | 1 | 0,32 |

1 | 10 | 0,25 |

11 | 20 | 0,18 |

21 | 50 | 0,12 |

51 | 100 | 0,1 |

101 | 350 | 0,06 |

351 | 850 | 0,05 |

851 | 1400 | 0,04 |

1401 | 3000 | 0,03 |

Application

It is a special type of wire used in electronics. It is made up of several wires covered with an insulating film, twisted and connected in parallel at their ends. The use of many wires in parallel increases the surface area of the conductive surface and thus reduces the influence of the skin effect *. For them, their applications are very diverse:

Electric automobile

Medicine-health (magnetic resonance equipment)

Renewable energy

Aeronautics / airspace

Railway industry

Electrical connections

*Skin effect: A phenomenon of electromagnetic origin dictating that at high frequencies, an electric current will flow rather on the surface of a conductor than inside.

Source : https://www.allaboutcircuits.com

Le câble de Litz est la réunion de plusieurs fils de Litz.

Le câble de Litz est la réunion de plusieurs fils de Litz.

Le câblage se fait en couches concentriques, pour réaliser la section nécessaire (7 x 7 x 37).

Nous pouvons aussi fabriquer sous forme carrée ou rectangulaire, selon le besoin.

Nous pouvons également mettre une couche d’isolation textile.

Le câble de Litz se définit par le nombre de fils et le diamètre unitaire des fils :

Exemple : 120 X 0,10mm = 120 brins de diamètre 0,10mm.

Why use Litz Wires?

Technical specifications

Nous réalisons les câbles de Litz de différentes manières suivant les recommandations du Bureau d’Études. TESORAX les fabrique avec les fils assemblés dans le même sens et avec un pas de toron inférieur à 60mm. Sur demande, et pour satisfaire les besoins de nos clients, nous pouvons les former en section rectangulaire ou carrée afin de réduire le volume de bobinage. Les fils de Litz peuvent en effet servir au bobinage, comme le bobinage des moteurs électriques par exemple, moteurs que nous proposons ici. La fabrication de nos câbles de Litz fait appel à des matériaux permettant un soudage direct sans besoin d’utiliser une procédure mécanique. Avant soudage, le câble de Litz doit être immergé dans un agent décapant et ensuite dans un bain d’étain (60%) et de plomb (40%) à une température de 375°C à 400°C. Le temps d’immersion dépend du nombre de fils et du diamètre du câble.

Winding losses

The losses produced in the coils are due to the factors:

Losses in the conductor:

Joule effect

Eddy currents

Capacity losses

Losses due to the hysteresis effect of the core

The first two factors appear in the coils and the third in those having a ferromagnetic core. We will analyze the first two factors in order to justify the use of the Litz cable.

Losses in the conductor

The Joule effect is known that electrical conductors heat up by the passage of current, which has the effect of increasing the ohmic resistance of the conductor and therefore reducing the possible current in the same section. Apparently, it is possible to increase the section in order to decrease the Joule effect, but this would lead to an increase in losses due to eddy currents. Changing the section is therefore not a solution, once it has been defined. We can do as follows: once the section of the conductor has been determined, in order to eliminate the film effect, we can join together, at the calculated section, enamelled cables; in this way we obtain a section which will be maintained during the whole working cycle of the coil. The thinner the threads, the better the result, due to the dandruff effect. However, this solution is expensive. We recommend the ideal calculation of the cross-section which can be studied on a case-by-case basis by a technician.

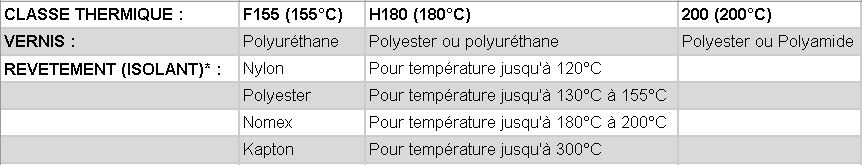

To calculate the skin current, use the following formula which gives us the current level (depth):

Pour calculer le courant pelliculaire, utiliser la formule suivante qui nous donne le niveau (profondeur) de courant:

e = Thickness to be calculated //

p = Resistivity of the conductor

u = Permeability of the conductive material // f = Current frequency

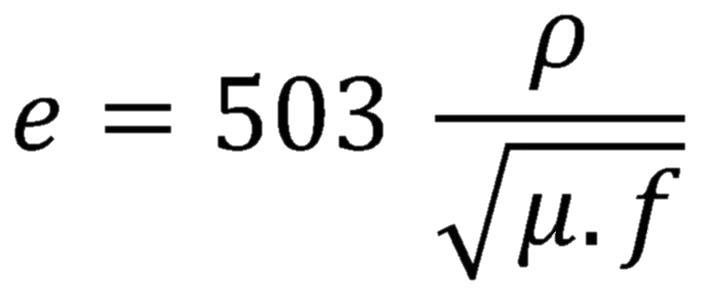

For a copper conductor, the formula takes the following form:

The value is given in millimeters.

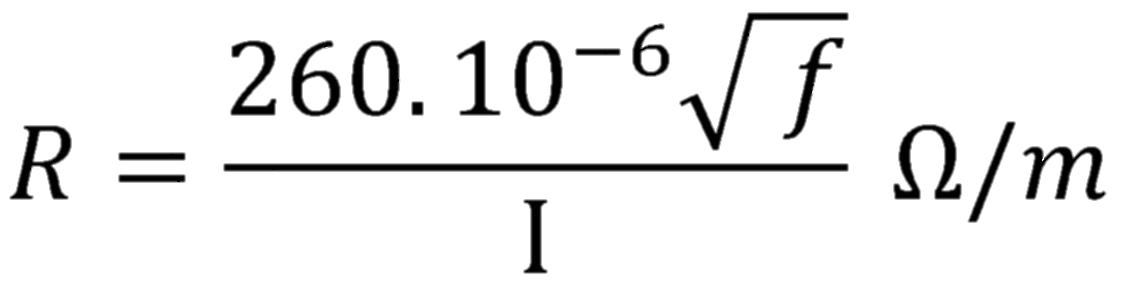

The resistance of an alternating current conductor is given by:

![]()

I = Perimeter in mm of the conductor section.

For copper, the formula becomes:

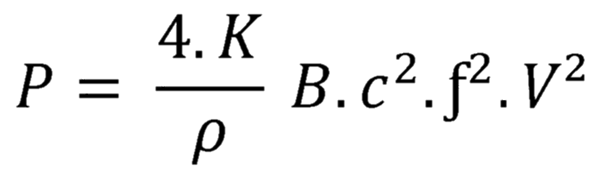

Eddy currents

When a ferromagnetic material is introduced into an alternating magnetic field, in addition to magnetization, an induced voltage is created; this produces an induced current which depends on the resistivity of the material. The current induced in the material is consumed in the form of heat (Joule effect) which is given by the formula:

P = Power dissipated by eddy currents // K = Constant

p = Resistivity of copper // B = Maximum induction passing through the material

c = Thickness of the ferromagnetic material // f = Frequency // V = Volume of the ferromagnetic material

Capacity losses

Deux conducteurs avec différents potentiels accumulent, en même temps, de l’énergie électrique. Les fils servant à la fabrication de bobines ont cette particularité, ce qui nous permet de parler d’une somme de capacités distribuées entre les différentes spires de celle-ci. Les bobines étudiées sont soumises à une tension alternative de haute fréquence, proche de la fréquence de résonance ce qui nous donne une impédance très élevée comme si elles étaient en parallèle avec la résistance ohmique et le coefficient auto-inductif de la bobine. Ces concepts nous donnent la conclusion que la capacité de la bobine seule est égale à 0,55 fois le diamètre en cm de celle-ci. Nous pouvons modifier la capacité de la bobine en :

- Studying its dimensions

- Chercher le meilleur enroulement

- Distributing the currents in the coil and Insulating the conductors

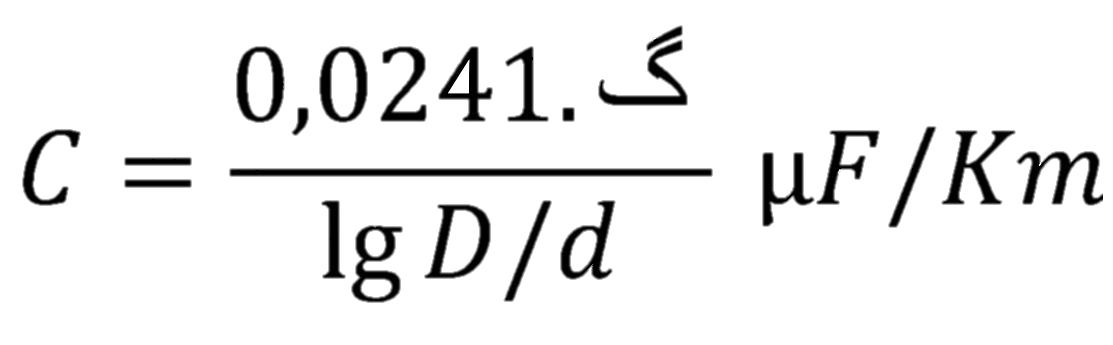

The capacitance between two conducting wires is:

گ = Dielectric constant of the insulation // D = Diameter of the wire with the insulation // d = Diameter of the bare wire

Once the insulation is chosen - which must have a very low dielectric constant and must meet our objectives - we must analyze the D / d relationship. The lower it is, the better the capacity will be. The engineer must decide on the best solution taking into account the maximum current that must pass through each wire and the voltage carried by the wires. Proper stranding of the wires forming the Litz cable will give the necessary uniformity for the capacitive distribution through this cable, so as to increase the quality factor of the coil. By placing a spiral of natural silk, polyester or any other fiber that meets our specifications, as a support for stranding enamelled wires, we do not increase the factor D. In addition, the pitch of the fiber must be perfectly sized for that the Litz cables are not too rigid, in order to allow a good winding without increasing the apparent inductance created between the spirals. The IgD / d relationship is a multiplying factor for the inductance and should be as small as possible, and is a dividing factor for the capacitance for which it should be as large as possible.

It is up to the engineer who calculates the coil to determine the parameters to be considered in the study of the circuit:

- Ohmic resistance

- Total induction

- Total capacity

The end result should be a coil ready for use in the circuit, with the best performance, lowest volume, and best quality while having the lowest resistance loss.

Litz cables are used to:

- Reduce losses by Joule effect

- Reduce losses due to eddy currents

- Use smaller magnetic cores

- Obtain capacity in small coils

- Get better quality

- Easy handling of cables for winding, due to wires fixed together

- Extra-flexible cables allowing core winding with a very small bend radius

Manufacturing standards

TESORAX ensures the manufacture according to the DIN 46.447 standard, and studies the cables according to the criteria:

- Number of wires depending on the cable diameter

- The type of insulation

- The support system

- Enamelled copper must be tinned. The outside diameter and other properties of the enamelled copper wire are selected by the manufacturer if the customer does not formally specify them. The outside diameter without insulation is the basis for calculating the outside diameter of the insulated cable: this is not used during reception checks.

High frequency cables (Litz cables) are defined by:

- Thickness of each elementary wire

- Total number of wires and bundling

- No stranding

- Insulating

The DIN 46.447 standard defines the types of cables according to each of these 4 criteria. Any question about the effective cross section of the conductor is defined as follows:

- Preset effective section: 0.70mm²

- Individual wire diameter: 0.10mm, i.e. a section of 0.007854 mm²

- Corresponding number of threads: 0.70 / 0.007854 = 89.13 theoretical threads. 90 threads will be used. The studied cable will have the following composition: 90x 0.10mm

Do not hesitate to contact us for any information: Our design office will be able to guide you in the cable solution that suits you best.