COPPER CABLE

INTRODUCTION

The copper cable is the essential equipment for any installation of electrical equipment.

The properties of copper make it an ideal material for ensuring the integrity of energy transfer. Indeed, whether bare or tinned, it is an exceptional electrical conductor, and its properties are exploited in many areas of the electrical industry.

CABLE PROPERTIES, BARE OR TINNED COPPER

Copper is a rarefying metal and is considered semi-precious. It is considered to be the best conductor among non-precious metals, that is why this meterial is used a lot for conductors of electric current.

Its electrical conductivity is considered to be nearly 60% higher than that of aluminum (Al), its most popular competitor. However, Aluminium has also some defects compared to copper. For example:

Température de fusion très basse, de l’ordre de 660°C pour l’Aluminium, contre plus de 1080°C pour le Cuivre

Although malleable, aluminum is not stretchable, which is particularly problematic when using very thin stranded conductors

Significant risk of oxidation

Our material is manufactured with the greatest care, so as to preserve its purity so as not to degrade its high level of electrical conductivity. Our manufacturing processes exclude any treatment of the surface of our cables, while avoiding their oxidation. Indeed, an oxidized surface would result in a significant loss of the conductivity of the material.

Also, the flexibility that we apply to our copper cables allows a very varied use in the electrical field, as well as an ease in its handling, its installation and its use. We thus obtain a flexible cable, perfectly maintained and offering flexibility in all directions.

CORE OF CABLES - conductive part

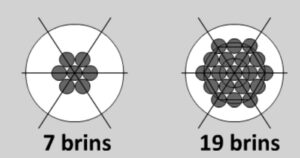

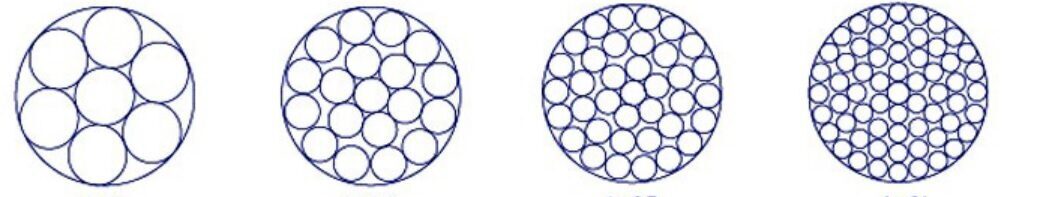

The soul is the conductor of the cable. Its role is to conduct the electric current, and must present a resistivity (ρ in Ω.m) very low in order to reduce thermal losses (= losses by Joules effect). The core used in the manufacture of our cables is copper, which has a resistivity of 1.7 × 10-8 Ω.m, lower than that of aluminum for comparison. The core of the cables is defined by the number of strands x diameter of a strand.

FLEXIBILITY & CLASSES

The flexibility of a cable or a conductor depends on the composition of the conductor. In this case, for the same section, the flexibility will depend on the number of strands used. The more strands used, the smaller the section of the strands used will be. The NF C 32-013 standard defines 4 flexibility classes:

Class 1: Massive core for fixed installations

Class 2: Rigid wired core for fixed installations

Class 5: Flexible copper core for flexible installations

Class 6: Extra-flexible copper core for flexible installations

Our copper cables offered are class 5 and 6. We also offer class 2 cables.

APPLICATIONS

Here are some examples of applications for this type of connection: telecommunications, connections, the manufacture of various electrical equipment, protection and earthing equipment, sockets, lightning rods, control and instrumentation systems, industrial automation, centers transformation, etc.

TESORAX BARE COPPER CABLES

We use copper as a conductive material. More precisely, it is annealed electrolytic bare or tinned copper, according to standard EN 13602. The conductive copper wires are arranged in concentric layers (7-19-37-61) to ensure perfect cable redundancy. The wires can be arranged in 2 wiring directions: Left or right (one per layer), also called not in S or not in Z (S-lay / Z-lay). The case of a single direction is called UNILAY.

Ensuite, la section que l’on appelle section transversale, peut être circulaire ou carrée. Il est possible de fabriquer les cables avec des fils de diamètres 0,10 ou 0,25 mm, avec lesquels nous pouvons constituer des sections de 0,75 mm² à 1200 mm².

Sur commande, nous pouvons produire et isoler les câbles avec différents matériaux :

Extrude (PVC, LSHF, SILICONE, PE, etc.)

Tape and thread (nylon, Nomex, polyester, Kapton, mica glass and fiberglass)

Nous proposons également des cables encore plus flexibles, ou extra flexibles, que nous appelons cables ronds. Pour obtenir cette souplesse, nous les fabriquons avec des fils de diamètre 0,07mm ou 0,10mm.

Nous avons plusieurs références standardes en stock, tels que le 25mm², 50mm² ou 70mm².

Contact us for your requests of flexible bare copper cables.

TECHNICAL DATA

Bare copper / tinned conductor (0.10 mm)

Reference # Bare Copper | Tinned copper reference # | Section (mm²) | Ø exterior (mm) | Mass (g/m) | Résistance cuivre nu (Ω/Km à 20 °C) | Résistance cuivre étamé (Ω/Km à 20 °C) | Nb of wires |

|---|---|---|---|---|---|---|---|

NF-14 Nº 1 | NF-14 Nº 1E | 0.75 | 1.15 | 7.5 | 26 | 44403 | 98 |

NF-14 Nº 2 | NF-14 Nº 2E | 1 | 1.4 | 10 | 19.5 | 20 | 126 |

NF-14 Nº 3 | NF-14 Nº 3E | 1.5 | 1.9 | 15 | 13.3 | 44390 | 189 |

NF-14 Nº 4 | NF-14 Nº 4E | 2.5 | 2.3 | 25 | 7.98 | 8.21 | 322 |

NF-14 Nº 5 | NF-14 Nº 5E | 4 | 3.1 | 40 | 4.95 | 44444 | 511 |

NF-14 Nº 6 | NF-14 Nº 6E | 6 | 4 | 60 | 3.3 | 3.39 | 770 |

NF-14 Nº 7 | NF-14 Nº 7E | 10 | 4.9 | 100 | 1.91 | 1.95 | 1274 |

NF-14 Nº 8 | NF-14 Nº 8E | 16 | 6.3 | 160 | 1.21 | 1.24 | 2044 |

NF-14 Nº 9 | NF-14 Nº 9E | 25 | 8.25 | 250 | 0.78 | 0.795 | 3185 |

Packaging: Crowns of 50 or 100 or 200 meters.

Approximate weight : About 10 grams per meter per mm². Example: 1mm² = 10g / meter.

Dimensions : Any modification of the composition influences the dimensions and the weight of the conductors, knowing that the effective section is greater than the nominal section. These specifications are given for information only and are subject to change.

Bare / tinned copper conductor (0.25 mm)

Reference # Bare Copper | Tinned copper reference # | Section (mm²) | Ø exterior (mm) | Mass (g/m) | Résistance cuivre nu (Ω/Km à 20 °C) | Résistance cuivre étamé (Ω/Km à 20 °C) | Nb of wires |

|---|---|---|---|---|---|---|---|

NF-15 Nº 1 | NF-15 Nº 1E | 2,5 | 2.4 | 25 | 7.98 | 8.21 | 49 |

NF-15 Nº 2 | NF-15 Nº 2E | 4 | 3.5 | 40 | 4.95 | 5.09 | 84 |

NF-15 Nº 3 | NF-15 Nº 3E | 6 | 3.7 | 60 | 3.3 | 3.39 | 126 |

NF-15 Nº 4 | NF-15 Nº 4E | 10 | 5 | 100 | 1.91 | 1.95 | 203 |

NF-15 Nº 5 | NF-15 Nº 5E | 16 | 5.7 | 160 | 1.21 | 1.24 | 329 |

NF-15 Nº 6 | NF-15 Nº 6E | 25 | 8 | 250 | 0.78 | 0.795 | 511 |

NF-15 Nº 7 | NF-15 Nº 7E | 35 | 9.4 | 350 | 0.554 | 0.565 | 722 |

NF-15 Nº 8 | NF-15 Nº 8E | 50 | 11 | 500 | 0.386 | 0.393 | 1 026 |

NF-15 Nº 9 | NF-15 Nº 9E | 70 | 13.5 | 700 | 0.272 | 0.277 | 1 615 |

NF-15 Nº 10 | NF-15 Nº 10E | 95 | 16 | 950 | 0.206 | 0.21 | 1 938 |

NF-15 Nº 11 | NF-15 Nº 11E | 120 | 18 | 1200 | 0.161 | 0.164 | 2 451 |

NF-15 Nº 12 | NF-15 Nº 12E | 150 | 19 | 1500 | 0.129 | 0.132 | 3 078 |

NF-15 Nº 13 | NF-15 Nº 13E | 185 | 21 | 1850 | 0.106 | 0.108 | 3 768 |

NF-15 Nº 14 | NF-15 Nº 14E | 240 | 23.5 | 2400 | 0.0801 | 0.0817 | 4 902 |

NF-15 Nº 15 | NF-15 Nº 15E | 300 | 27 | 3000 | 0.0641 | 0.0654 | 6 118 |

NF-15 Nº 16 | NF-15 Nº 16E | 400 | 31 | 4000 | 0.0486 | 0.0495 | 8 113 |

NF-15 Nº 17 | NF-15 Nº 17E | 500 | 34.5 | 5000 | 0.0384 | 0.0391 | 10 241 |

Packaging: 100 meter rolls or wood reels depending on the section

Approximate weight : About 10 grams per meter per mm². Example: 6 mm² = 60 g / meter. 300 mm² = 3000 g / m

Dimensions : Specifications are given for information and are subject to change

THE FLEXIBLE BARE COPPER CONNECTION: THE INDUSTRIAL BACKBONE

Flexible bare copper cable holds a special place within the industry, where its versatility, reliability and exceptional electrical properties make it an essential element for a variety of critical sectors. For decades, this material has been a key player in the evolution of the industry, offering robust connectivity, optimal energy efficiency and proven resistance to the most demanding challenges.

In the field of energy, this flexible cable plays a vital role in electrical distribution. Its superior conductivity enables efficient transfer of electricity over long distances, minimizing losses and ensuring a constant flow of energy to homes, businesses and critical infrastructure. Additionally, its ability to withstand harsh environmental conditions makes it a preferred choice for underground and overhead power cables, ensuring reliable and secure distribution.

In the telecommunications industry, flexible bare copper continues to play a vital role in high-speed data transmission. Whether for terrestrial or submarine communication networks, this material offers high bandwidth, allowing the fast and reliable transfer of essential data. Its durability against weather and electromagnetic interference makes it a top choice for communications infrastructure, supporting our interconnected world.

The construction industry also benefits greatly from flexible bare copper. Used in grounding systems, electrical wiring and security installations, this material provides critical electrical stability for buildings and infrastructure. Its flexibility is a major asset for installation in tight spaces, allowing seamless integration into modern structures.

In summary, this type of flexible cables is much more than just a material in the industry. It is a fundamental pillar, supporting energy, communication and construction, and enabling the uninterrupted functioning of our modern society. Its history of reliability and its pivotal role in a multitude of applications make it an essential element, shaping the industrial landscape and supporting our technological advances.