COPPER WIRES FOR ALL YOUR NEEDS

Here we present the types of wires that we use ourselves and offer to manufacturers. We describe bare copper wire and enameled copper wire here, but other types of wire may be available, upon request. We offer single wires with diameters of 0.03mm to 5.0mm.

We offer to package the wires in different plastic spools (P-125/160/250).

It is possible to use single copper wires in a wide variety of fields, such as electronics, robotics , renewable energies, winding of rotating machines (used in the winding of our electric motors for example, etc but also for individuals. Also copper is the element most commonly used in the material of electrical wire conductors.

As a reminder, copper is a material known for its very high conductivity, its properties also making it malleable and very resistant .

What type of wire to choose?

The type of copper (bare, enameled, tinned, etc.) will depend on the use of the wire. The wire diameter is also to be chosen according to the application.

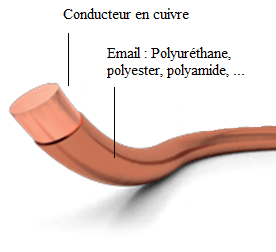

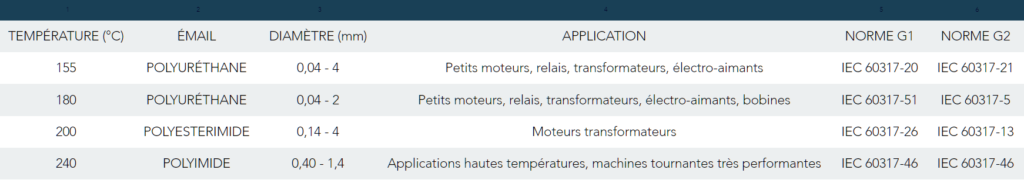

Enamelled copper wire is copper wire covered with varnish, enamel, coating. This coating can be of different material, such as polyester, polyurethane, polyimide, etc. The table below shows the type of varnish according to the temperature to which the wires must withstand in operation. We have drawn up a non-exhaustive list of applications requiring this type of wire, depending on the temperature. The joined enamelled wires form what are called Litz wires. You will find more information and the advantages of Litz's wires by clicking here.

Conductor

This type of wire is a polished annealed electrolytic copper wire (99%), made with Cu-ETP. It is in fact annealed copper, that is to say relatively malleable, the properties of which must allow an elongation of up to 25%.

Varnish

The wires are covered with a layer of enamel, a coating. This enamel layer can be of different material, which will be chosen according to the maximum temperature to withstand.

Applications

This type of wire can be used in various fields, such as electronics or winding, depending on the type. Some examples :

Thermal class (°C) | Class H, 180°C |

Insulation | Polyurethane |

Insulation | Top coat – | – |

Insulation | Bonding layer – | – |

Production range (mm) | 0.03 -1.10 mm |

Standards IEC | IEC 60317 – 51 |

UL certified | On demand |

Thermal class (°C) | 180°C |

Thermal shock (°C) | ≥ 200°C |

Passage temperature (°C) | ≥ 230°C |

Soldering temperature (°C) | > 380°C |

Bonding temperature (°C) | Not applicable |

Softening temperature (°C) | Not applicable |

Normal resistance to solvents | 3H – 4H |

Dipping Varnish Resistance | Good |

Refrigerant resistance | Not applicable |

Transformer oil resistance | Not applicable |

Specific characteristics | Excellent low temperature weldability |

Areas of use | Electromecanique, automotive |

To note

The enamelled conductor is therefore defined according to whether it is weldable or not, according to the temperature class and according to the number of layers of varnish.

- The temperature indices are called thermal class, and indicate the temperature at which the copper wires can operate for about 20,000 hours.

- Polyurethanes can be welded. In theory, this does not require stripping beforehand. This is because the coating layer evaporates with heat. This is called weldable. They can also be of different colors (black, purple, green, blue) but are mostly red or yellow. Note that the color has no effect on the insulating capacity of the varnish.

- Polyesterimides are brown in color. They are generally non-weldable, since they must be pickled before welding.

- Polyimides must also be pickled before welding, and are therefore considered as non-weldable.

- The grade indicates the number of enamel layers. Grades 1 and 2 are the most commonly used. The number of layers increases the insulation property of the wire. Grade 2 is therefore thicker and offers better strength than grade 1. Grade 3 is also possible.

The total diameter of the wire (nominal + with varnish) increases according to the grade. This must be taken into account, particularly concerning the installation and the conditions of use (size, contact with the environment, etc.).

You can consult here the calculations of the filling rate according to the wire diameter and the applied grade.

Characteristics

These are annealed, bare or tinned electrolytic copper wires. The wires are of chemical and electrical composition according to standard EN13602. The wires are delivered in coils of P-150 to P-250, depending on the quantities requested.

Applications

Bare or tinned copper wires can be used for a variety of electronic and electrical conductor construction applications. The wires can be used individually or combined in strands.

NOTE

The types of wires shown here are indicative. On request, we can in fact supply wires of different shapes (square, rectangular), of different diameters, and of different material (silver, etc.).

Do not hesitate to contact us for any request. Our technicians will be happy to answer you.