Download our Motors catalogue - general

CHOOSE YOUR ELECTRIC MOTORS HIGH PERFORMANCE

STANDARD RANGE OR CUSTOMIZED SOLUTIONS

Your need is our project and will be the subject of a specific study

Low voltage electric motor IE1, IE2, IE3 and IE4 three&one-phase, asynchronous

High voltage electric motor, ATEXIIB explosion proof, IP23

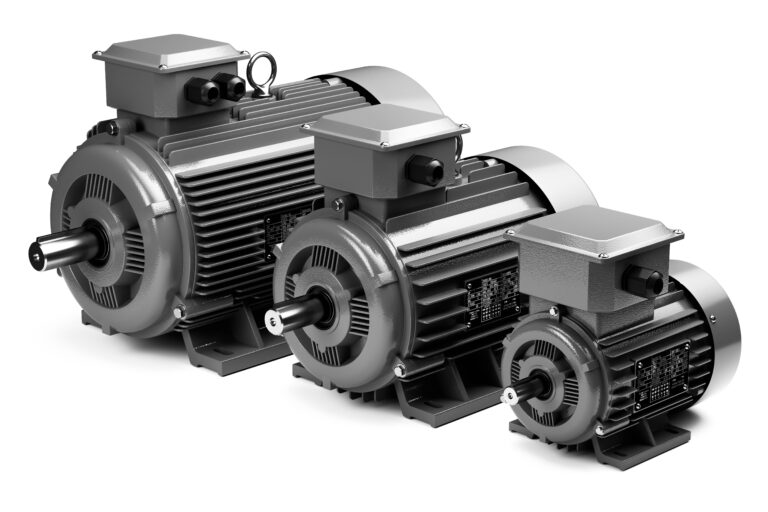

OUR ELECTRIC MOTOR RANGE

IE4 MOTORS

Aluminum | Cast iron

Power 2.2 - 230kW

Shaft height 100 - 315

Poles 2 | 4 | 6 | 8

Low voltage

50Hz | 60Hz

IE3 MOTORS

Aluminum | Cast iron

Power 0.75 - 630kW

Shaft height 80 - 400

Poles 2 | 4 | 6 | 8

Low voltage

50Hz | 60Hz

IE2 MOTORS

Aluminum | Cast iron

Power 0.75 - 355kW

Axis height 80 - 400

Poles 2 | 4 | 6 | 8

Low Voltage

50Hz | 60Hz

IE1 MOTORS

Aluminum | Cast iron

Power 0.06 - 355kW

Shaft height 80 - 355

Poles 2 | 4 | 6 | 8 | 10 | 12

Low voltage

50Hz | 60Hz

HIGH VOLTAGE MOTORS

Cast iron

Power 185kW - 1.8MW

Shaft height 315 - 630

Poles 2 | 4 | 6 | 8 | 10 | 12

Low voltage

50Hz | 60Hz

ATEX IIB MOTORS

ATEX IIB cast iron

Power 0.75 - 315kW

Shaft height 80 - 315

Pole 2 | 4 | 6 | 8

Low voltage

50Hz | 60Hz

IP23 MOTORS

IE3 font | IE2 I IE1

Power 11 - 710kW

Shaft height 160 - 355

Pole 2 | 4 | 6

Low voltage

50Hz | 60Hz

OUR HIGH PERFORMANCE ELECTRIC MOTORS

Discover our range of electric motors from IE1 to IE4, as well as IP23, high voltage, medium voltage and EXD ATEX explosion-proof motors designed to meet all your needs. IE3 and IE4 motors offer unparalleled energy efficiency, saving you energy while reducing your carbon footprint. Our IE1 equipment, on the other hand, is a reliable and economical solution, ideal for applications where performance is essential.

Our IE1 equipment, on the other hand, represents a reliable and economical solution for a wide range of applications requiring a high-performance electric motor.

It is important to note that since 2011, the European Union has established strict standards regarding the energy efficiency of electric motors, in accordance with the European Regulation EU 2019/1781 . Our IE1 motors, although of high quality, are mainly intended for export, while our IE3 and IE4 motors are in full compliance with these standards within the EU. If you are looking for an electric motor that complies with current standards while optimizing your energy savings, our IE3 and IE4 solutions are the ideal choice. Explore our complete catalog to find the perfect engine for your specific needs.

Our motors are designed and manufactured in accordance with the parameters of the new European high efficiency standard IE1, IE2 and IE3. MS series are designed and manufactured in accordance with the parameters of the new European classification standard for IE1 and IE2.

With the exception of the OMD(H) IP23 range, all motors are completely enclosed, ventilated, with squirrel cage rotor. OMT2, MS and TA series from frame size 56 to 160 and OMT4 series from frame size 56 to 160 are supplied with an aluminum frame. The OMT1 and TC series from frame size 80 to 630 are equipped with a cast iron frame. The IEC 60034-2-1 standard defines three IE (International Efficiency) classes of single-speed three-phase cage induction motors, 50 Hz and 60 Hz; rated voltage up to 1000 V; service type S1 or S3 with a nominal duty cycle factor of 80% or more operating directly online.

Explore our complete catalog to find the perfect engine for your specific needs.

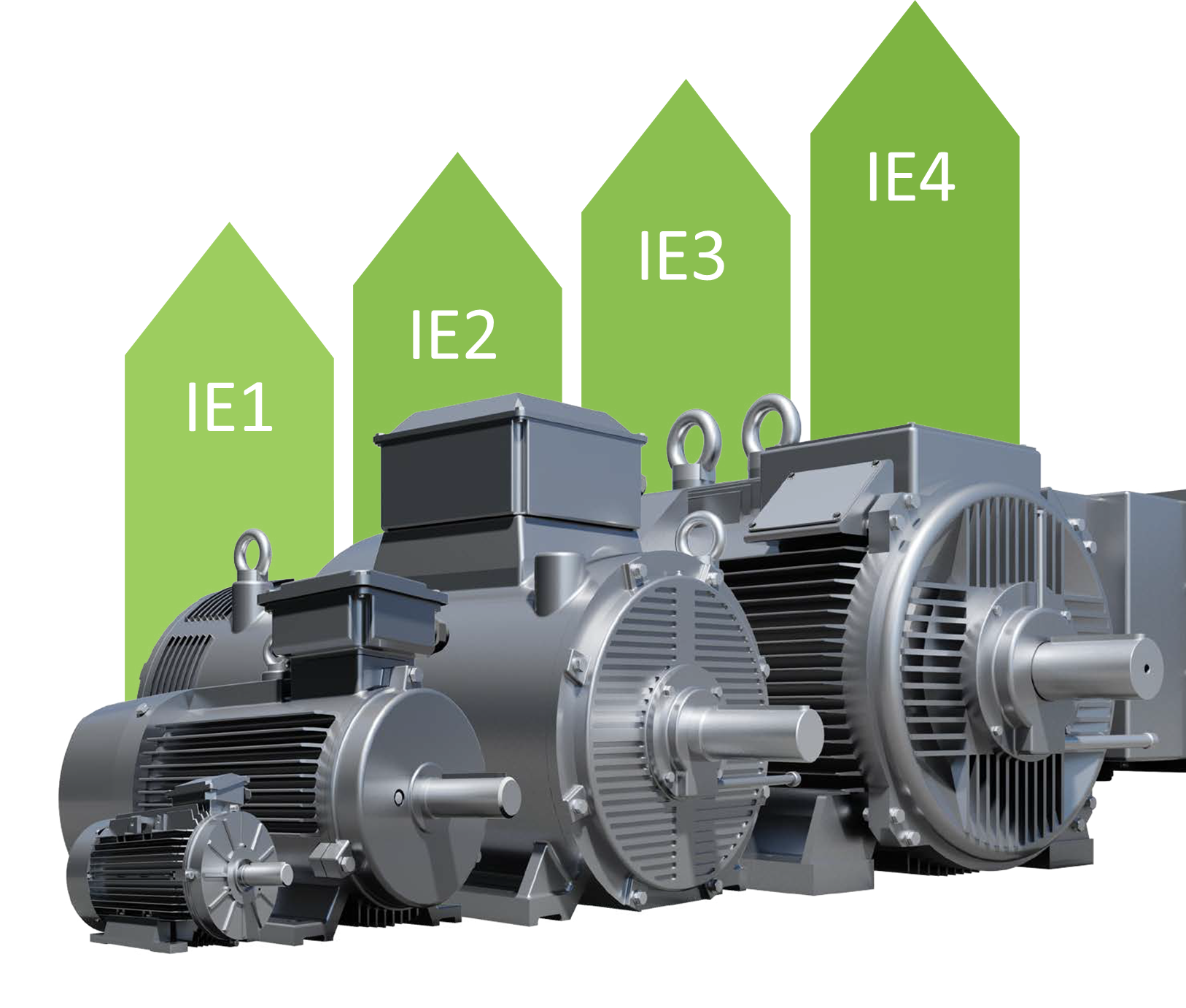

IE EFFICIENCY CLASSES

An international standard has been established with the aim of classifying the energy efficiency on an international level (IE) of low voltage three-phase asynchronous motors. This is the standard IEC /EN 60034-30.1.

This standard defines the different yields as follows:

- IE1 = Standard efficiency

- IE2 = High efficiency

- IE3 = Premium efficiency

- IE4 = Super premium efficiency

The EcoDesign EuP directive (2005/32/EC) sets out ecodesign requirements for energy-using products. This is Commission Regulation (EC) 640/2009 which specifies the efficiency requirements for electric motors and which introduces in all countries of the European Community the obligation of the minimum efficiency level IE2 from June 16, 2011. Higher minimum efficiencies will be made mandatory in the near future. IE3 efficiency will gradually become mandatory between 2015 and 2017. The regulation applies to three-phase squirrel cage motors at a speed of 50 Hz or 50/60 Hz in the power range from 0.75 kW to 375 kW in 2, 4 or 6 pole versions designed for continuous operation S1. Engines intended for exclusive sale outside the EU may still be supplied after June 16, 2011 with a lower efficiency level. The country of destination must be specified in the order.

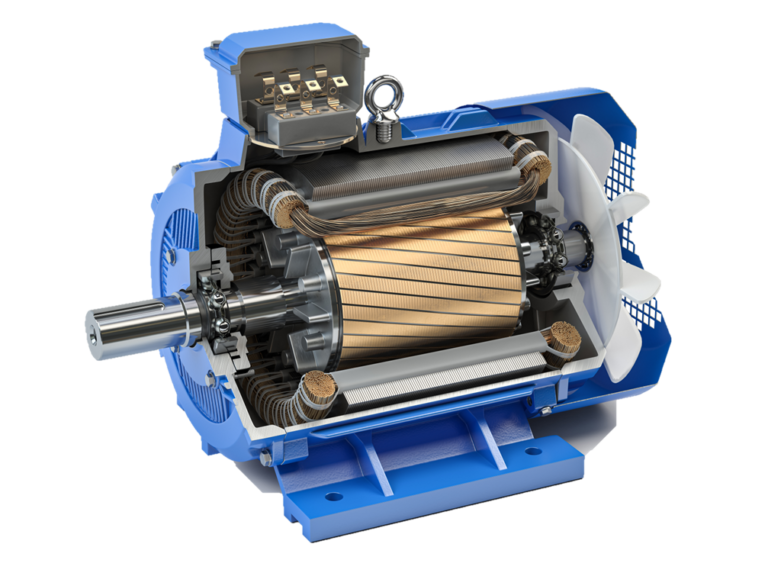

HOW AN ELECTRIC MOTOR WORKS ?

The electric motor is an electromechanical device whose main role is to convert electrical energy into mechanical energy, through the interaction between the electric current and the magnetic field, thus creating a rotation that powers a variety of industrial and domestic applications. . All electric motors have an inherent reversibility.

Modern electric motors take advantage of the efficiency of permanent magnets to generate precise and consistent motion. Making them essential in many industrial and technological applications.

Thus, we distinguish between different types: the direct current motor and the alternating current motor, which can be synchronous or asynchronous. Three-phase asynchronous electric motors can be supplied with 230/400v (star coupling) or 400/700v (delta coupling). To reverse the direction of rotation, simply reverse two phases on the terminal block of the terminal box.

Electric motors, also called induction machines, are a type of machine that works with alternating current, and which does not require a connection between the stator and the rotor.

In the past, the asynchronous motor was in direct competition with the synchronous motor for high power applications. However, with the evolution of power electronics, its position has been consolidated. It is found in various fields such as transport (subways, trains, ships), industry (machine tools) as well as in household appliances. Asynchronous machines are also used as generators, especially in wind turbines.

Elements making up an electric motor:

An electric motor is a complex device made up of several essential elements that work in tandem to convert electrical energy into mechanical motion. The main components of an electric motor include:

- Stator: The stator is the fixed part of the electric motor and houses the copper wire windings. It creates a stable magnetic field when electric current flows through it.

- Rotor: The rotor is the moving part of the motor and is placed inside the stator. It is also made of copper wire windings, but these are mounted on a rotating axis. When electric current passes through the rotor, it reacts with the magnetic field of the stator to generate the rotational motion.

- Collector (for DC motors): DC motors use a collector to reverse the polarity of the rotor windings as it spins. This allows the rotor to continue spinning in one direction.

- Switch (for AC motors): AC motors use a switch to reverse the direction of electrical current in the rotor at regular intervals, which maintains rotation.

- Levels: Bearings are supporting components that reduce friction and allow the rotor to spin smoothly. They are essential for engine durability and performance.

- Box: The electric motor box or enclosure protects internal components from external elements and provides a sturdy structure for mounting.

- Connectors and cables: Electrical cables and connectors connect the motor to an electrical power source, allowing the transmission of current necessary for the motor to operate. For example, we find enamelled copper wires (follow this link for more technical explanations on enameled copper wires), or even the Litz wires, as defined here.

These elements work together to create the rotating motion needed for many applications, from fans to industrial machines to electric vehicles. Understanding the composition and operation of an electric motor is essential to get the most out of this technology that is omnipresent in our daily lives.

TECHNICAL DATAS

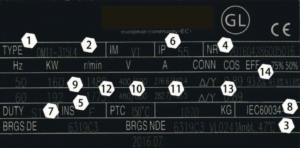

NAME PLATES

1 Engine type

2 Construction

3 Ambient temperature

4 Factory number

5 Thermal class

6 Protection

7 Mode

8 Standards

9 Puissance [kW]

10 Voltage [V]

11 Intensity [A]

12 Speed [rpm]

13 Power factor

14 Efficiency

MOUNTING

Our motors are available in IM B3, IM B5, IM B14 and other derivative designs and are manufactured in accordance with IEC 60034-7

PROTECTION

The standard protection of our motors according to IEC 60034-5 is IP55: closed housing, fan cooled, protection against the penetration of dust and water jets from all directions. Motors with IP56 protection (closed housing, protection against ingress of dust and strong water in steel) are available on request. As standard, IP56 motors are equipped with forced ventilation (IC411 – IC416 or IC418). IP65 or higher motors are available on request. On request, our motors can also be offered without fan (IC410). In this case, properties, performance data and other technical data will be provided upon request. The forced fan is protected by a fan cover with IP20 protection in accordance with applicable safety standards. Motors for vertical mounting (V1, V5 and V15) are equipped with a rain cover. The terminal boxes, made of aluminum and cast iron, are protected IP55 or IP56. Excluded from the above description are our IP23 motors in low, medium and high voltage designs.

GENERAL MANUFACTURING CHARACTERISTICS

The motors are designed and produced in accordance with international standards. The OMT1 series is available from size BG80 to BG630, OMT3 from BG80 to BG355 and TC from BG80 to BG355. Housings, flanges, shields and terminal boxes are made of cast iron, fan covers are made of sheet steel. OMT2 and OMT4 series are available from size BG56 to BG160, TA and MS series from BG56 to BG200. The housing and terminal box are made of aluminum, the fan covers are made of sheet steel. The flanges are made of gray cast iron. The OMT1 series terminal box in sizes BG80 to BG280 and in BG400 can be mounted rotating 90° as standard, while sizes BG315 and BG355 can be mounted 180°. On request, terminal boxes can be offered, each of which can be mounted at 90°. The terminal box (from size BG56 to BG280), installed as standard on the top of the TC series, can be rotated by 90° and the TC motors can be converted to a motor with a left or right-handed terminal box. Standard fans are made of nylon, polyethylene or polypropylene. Aluminum fans can also be offered upon request. The feet are removable on the following engines:

- OMT2 series: BG56 to BG160

- OMT4 series: BG56 to BG160

- TCR series: BG80 to BG280

- TA series: BG63 to BG160

ROTOR BALANCING

The motors are dynamically balanced with a half key and fall under vibration stage A classifications in accordance with IEC 60034-14. If particularly smooth operation is required, a version with reduced vibration behavior according to grade B is available. The following table gives the effective vibration values for normal balancing (A) and in degree B.

| Oscillation size sleep | Shaft height H (mm) | 56 ≤ H ≤ 132 | 132 ≤ H ≤ 280 | H ≥ 280 | ||||||

| Machine Assembly | S eff | V eff | a eff | S eff | V eff | a eff | S eff | V eff | a eff | |

| µm | mm/s | m/s² | µm | mm/s | m/s² | µm | mm/s | m/s² | ||

| A | FREE MOUNTING | 25 | 1,6 | 2,5 | 35 | 2,2 | 3,5 | 45 | 2,8 | 4,4 |

| FIXED MOUNTING | 21 | 1,3 | 2 | 29 | 1,8 | 2,8 | 37 | 2,3 | 3,6 | |

| B | FREE MOUNTING | 11 | 0,7 | 1,1 | 18 | 1,1 | 1,7 | 29 | 1,8 | 2,8 |

| FIXED MOUNTING | – | – | – | 14 | 0,9 | 1,4 | 24 | 1,5 | 2,4 | |

COOLING

The type of cooling is indicated by the IC (International Cooling) code according to IEC 60034-6. Standard design motors of sizes BG56 to BG355 are offered with cooling type IC411 with one fan for both directions of rotation. All sizes can be offered with cooling type IC416 upon request. In this case, a suitable fan with appropriate reinforcement is installed in the fan hood to make the ventilation independent of the speed.

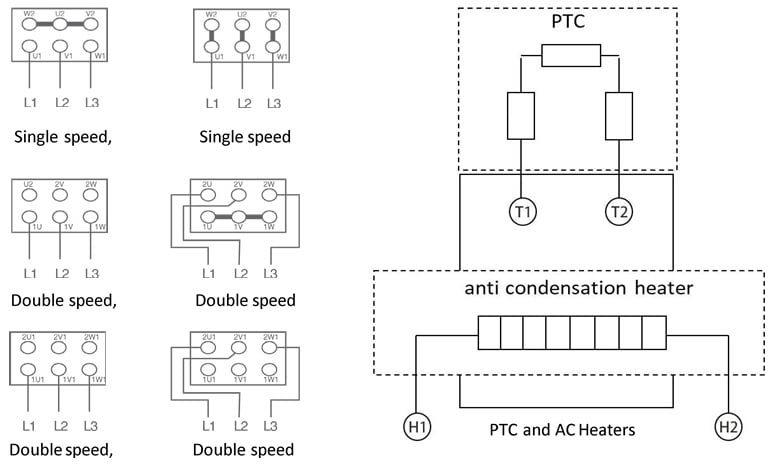

CONNECTION

Our motors are generally connected in delta (Δ) from 3 kW to allow star-delta (Y/Δ) starting at a line voltage of 400V. On request and for particular applications, depending on the power and supply voltages, the motors can be star-coupled (Y). Wiring diagrams are shown below.

EVALUATIONS & TECHNICAL DATA

The characteristics indicated in the technical data sheets always refer to the S1 operating mode (continuous operation) at an ambient temperature of 40°C and a maximum altitude of 1000 m above sea level with an operating voltage of 400V – 50Hz. For operating conditions in which the motor reaches a temperature below the maximum temperature of insulation class B, the operating characteristics are guaranteed in accordance with the tolerances and recommendations defined in IEC 60034-2-1. The corresponding values are shown in the following table.

1 | Characteristics | Tolerances |

|---|---|---|

2 | EFFICIENCY | MOTOR POWER < 50KW -15% DI (1 - Ƞ) |

3 | MOTOR POWER ≥ 50 KW -10% DI (1 – Ƞ) | |

4 | POWER FACTOR | +1/6 (1 – COS ɸ) MIN 0.02 MAX 0.07 |

5 | LOCKED ROTOR CURRENT | +20% OF GUARANTEED VALUE |

6 | LOCKED ROTOR TORQUE | -15% + 25% OF GUARANTEED VALUE |

7 | PULL OUT TORQUE | -10% OF GUARANTEED VALUE |

8 | SLIP | MOTOR POWER < 1KW ±30% OF GUARANTEED VALUE |

9 | MOTOR POWER ≥ 50KW ±20% OF GUARANTEED VALUE |

THE THREE-PHASE ELECTRIC MOTOR

We offer a wide range of three-phase electric motors available in 220-400/380-420V – 380-420/660-720V. These are cast iron or aluminum induction motors, with squirrel cage, according to standard EN60034 (IEC).The three-phase electric motor is a major technological innovation in the field of electromechanics. It is a type of electric motor specially designed to operate with alternating current using three separate electrical phases.

Its versatility and high performance make it a preferred choice in various industrial sectors, such as transportation, manufacturing, and commercial applications. If you are looking for a reliable and efficient motor for your projects, the three-phase motor is certainly a solution to consider. Discover our three-phase range with 2, 4, 6, 8, 10 poles (up to 12 for high voltage motors), for rotational speeds from 500 to 3600rpm.

THE POWER ADVANTAGES OF ELECTRIC MOTORS

Electric motors are often underestimated in terms of power. Despite their compact size, they provide high torque from start-up, ensuring optimal performance. In addition, their quiet operation ensures a pleasant driving experience, without unpleasant vibrations. Electric motors provide instant acceleration and rapid response to inputs, making them an ideal choice for drivers seeking performance.

Another powerful advantage of electric motors is their ability to deliver consistent, maximum power over a wide rpm range. Unlike internal combustion engines, electric motors do not require gear changes to achieve their maximum power. This results in smoother driving and better vehicle control, particularly appreciated in situations requiring rapid acceleration or overtaking.

Finally, electric motors offer more precise power regulation, which helps optimize energy efficiency and reduce power losses. This ability to deliver precise and consistent power contributes to more enjoyable and economical driving.

WHAT IS AN ATEX ELECTRIC MOTOR?

The ATEX (=ATmosphere EXplosive) electric motor, also known as an explosion-proof motor, is designed for use in potentially explosive or flammable environments. The term "ATEX" comes from the European directive 2014/34/EU, which regulates equipment used in such environments.

ATEX solutions are built in such a way as to prevent any source of ignition that could trigger an explosion, minimizing the risks associated with gases, vapours, flammable liquids or dust. These machines are essential in certain industries. Indeed, we can cite oil and gas, chemicals, pharmaceuticals, petrochemicals, as well as in production and storage sites for potentially dangerous products.

By choosing the ATEX solution, you guarantee the safety of their operations while complying with strict safety regulations in environments at risk of explosion.

THE ELECTRIC MOTOR: AT THE HEART OF THE TECHNOLOGICAL FUTURE

As we move toward an increasingly technology-driven future, the growing importance of electric motors is becoming undeniably evident. This transition results from the convergence of several determining factors, including the widespread integration of artificial intelligence (AI) and autonomous systems.

Electric motors play a central role in this transformation, powering a growing variety of devices and applications that are redefining our daily lives. For example, AI requires increased energy efficiency to process huge volumes of data in real time, which largely relies on advances in electric motors.

Autonomous vehicles and drones, powered by advanced electrical devices, are revolutionizing mobility with a focus on safety and energy efficiency. Additionally, automated delivery systems, industrial robots and advanced medical devices also depend on the reliable and precise performance offered by electric motors.

In short, the future will be shaped by the increasingly widespread use of electric motors, which offer energy-efficient solutions and adapt to the needs of a society constantly evolving towards advanced and autonomous technology. Thus, electric motors are the fundamental foundation of this transformation, bringing efficiency and sustainability to a constantly changing world.

THE ELECTRIC MOTOR FOR A GREENER INDUSTRY

Electric motors play an essential role in the context of energy transition. Indeed they offer an innovative and efficient solution to reduce our dependence on fossil fuels.

By gradually replacing internal combustion engines in various sectors such as industry, transport and even household appliances, electric motors contribute significantly to the reduction of greenhouse gas emissions and the improvement of the air quality. Their high efficiency, low environmental impact and flexibility to integrate with renewable energy sources make them a central pillar of the global effort to create a more sustainable and environmentally friendly energy future.

By gradually replacing internal combustion engines in various sectors such as industry, transport and even household appliances, electric motors contribute significantly to the reduction of greenhouse gas emissions and the improvement of the air quality. Their high efficiency, low environmental impact and flexibility to integrate with renewable energy sources make them a central pillar of the global effort to create a more sustainable and environmentally friendly energy future.ELECTRICITY TRIUMPH OVER FOSSIL FUELS

Electricity is proving to be the indisputable central element of the energy transition, offering a multitude of advantages that propel it ahead of traditional fossil fuels. By emphasizing environmental sustainability through renewable sources, it drastically reduces greenhouse gas emissions and plays a vital role in maintaining healthy ecosystems.

1. Environmental Sustainability

First, by focusing its production on sources such as solar, wind and hydropower, electricity is emerging as a driving force for environmental sustainability. It reduces polluting emissions, thus promoting the fight against climate change and considerably improving air quality. This focus on cleaner, environmentally friendly energy is proving crucial in our quest for a more sustainable future.

2. Versatility of Use

Also, a major advantage of electricity lies in its ability to adapt to a wide variety of applications. It can power electric vehicles, provide energy for heating and lighting systems and support industry. This intrinsic versatility makes it an ideal choice for a smooth and successful energy transition, which also helps to significantly reduce our dependence on fossil fuels.

3. Energy Efficiency

In addition, electric motors significantly outperform their internal combustion counterparts in terms of energy efficiency. This more efficient conversion of energy into motion results in substantial savings in energy consumption. This improvement in efficiency is a key element for the responsible and rational use of our energy resources.

4. Energy Autonomy

Finally, by focusing on local production from renewable sources, electricity promotes the energy autonomy of nations, thus reducing their vulnerability to the fluctuations of international oil and gas markets. This autonomy reinforces economic stability and secures the long-term energy supply.

In short, electricity not only presents itself as an essential choice in the energy transition, but it also embodies an essential driver for a cleaner, safer and more prosperous energy future. Its contribution to environmental sustainability, its versatility, its superior energy efficiency and its role in energy autonomy make it a fundamental pillar of change towards a world centered on sustainable energy solutions.

LE CUIVRE DANS LES MOTEURS ELECTRIQUES : PERFORMANCE ET DURABILITÉ

Copper plays an essential role in the operation and performance of electric motors. Indeed, this metal with excellent electrical and thermal properties is an essential component of the coils and windings used in electric motors.

When an electric current passes through these coils, the copper offers a low electrical resistance, which helps to minimize the energy losses by Joule effect, thus ensuring a high efficiency of the machine. Additionally, copper is widely used in the manufacture of magnets, including rare-earth permanent magnets, which are frequently employed in electrical rotating machinery to create the magnetic field needed to convert electrical energy into mechanical motion. .

However, the link between copper and sustainability is complex, as the mining and production of this metal can have environmental impacts. It is therefore crucial to consider sustainability approaches, such as recycling copper, reducing its use through more efficient designs, as well as exploring alternative materials and emerging technologies to ensure electric motors continue to perform. move towards more environmentally friendly solutions.

HOW TO CHOOSE YOUR ELECTRIC MOTOR?

Choosing the optimal electric motor is a crucial step for the success of any project requiring electric propulsion. To make an informed decision, it is essential to take into account several technical parameters. First, determine the power required based on the workload, in watts (W) or kilowatts (kW). This will help you select the engine that can deliver the necessary power without oversizing.

Next, the rotational speed of the motor, measured in revolutions per minute (rpm) or radians per second (rad/s), is a determining factor. Make sure it matches the needs of your application. Torque, measured in Newton meters (Nm), is also crucial. It depends on the load to be moved or driven, and it is imperative to select a motor capable of providing the necessary torque while avoiding overheating.

The environment of use is another fundamental aspect. If your application is exposed to special conditions, such as extreme temperatures or high humidity, choose an electric motor adapted to these environmental constraints.

In addition, the supply voltage must be compatible with the chosen motor. Electric motors come in different voltages, such as 12V, 24V, 110V, or 220V, and it is essential to ensure that the supply voltage matches that of the motor.

Finally, consider the durability and reliability of the engine. Look at the IP protection class (Protection Rating) to assess resistance to dust and humidity. Also check the motor specifications for its estimated lifespan, as this can have a significant impact on long-term operating costs.

In summary, choosing the right electric motor involves careful analysis of power, speed, torque, operating environment, supply voltage, durability and reliability. By taking these parameters into account, you will be able to select the electric motor that will best meet the needs of your project, thus ensuring optimal performance and maximum energy efficiency.

Nous utilisons des cookies pour vous garantir la meilleure expérience sur notre site web.

Refuse non functionnal cookies